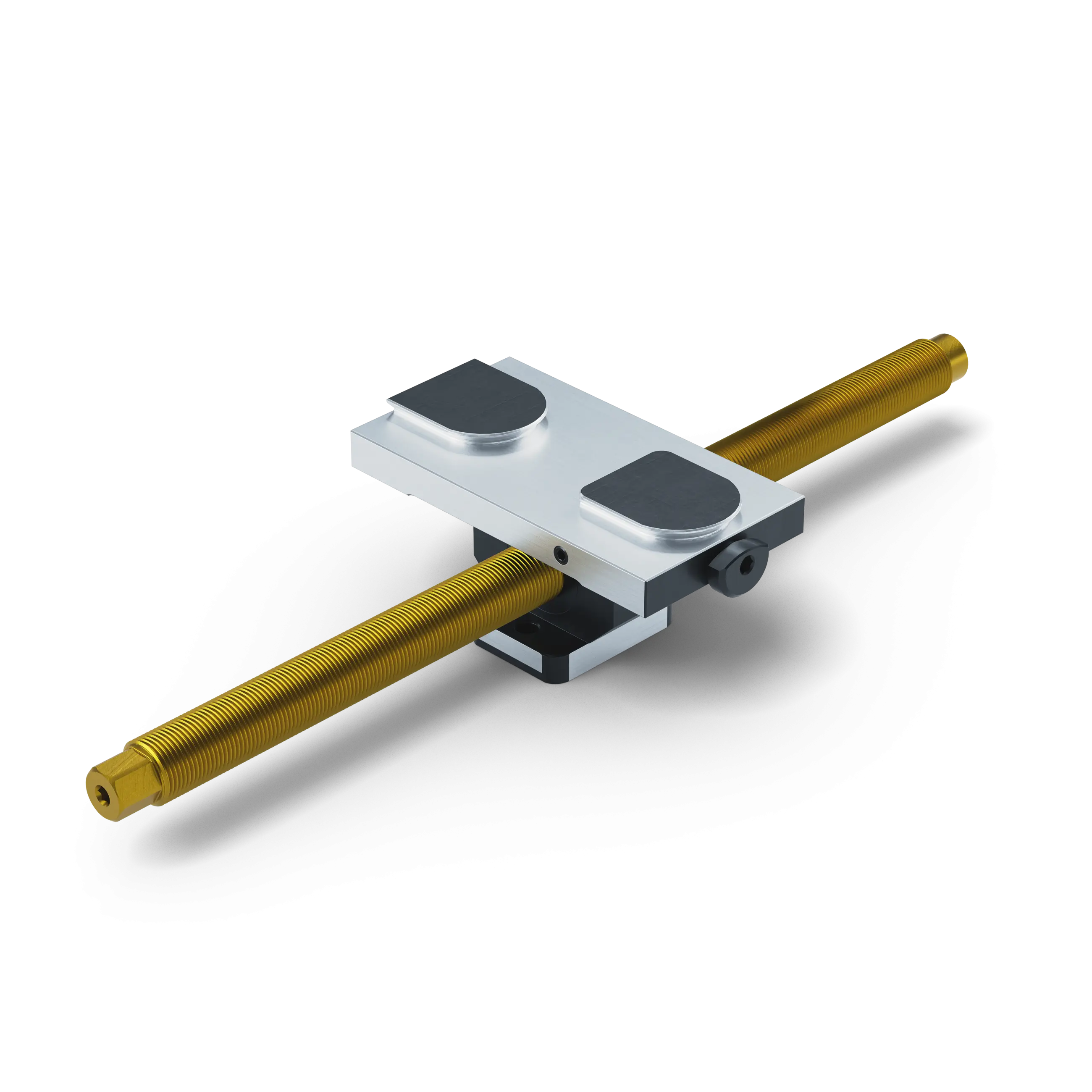

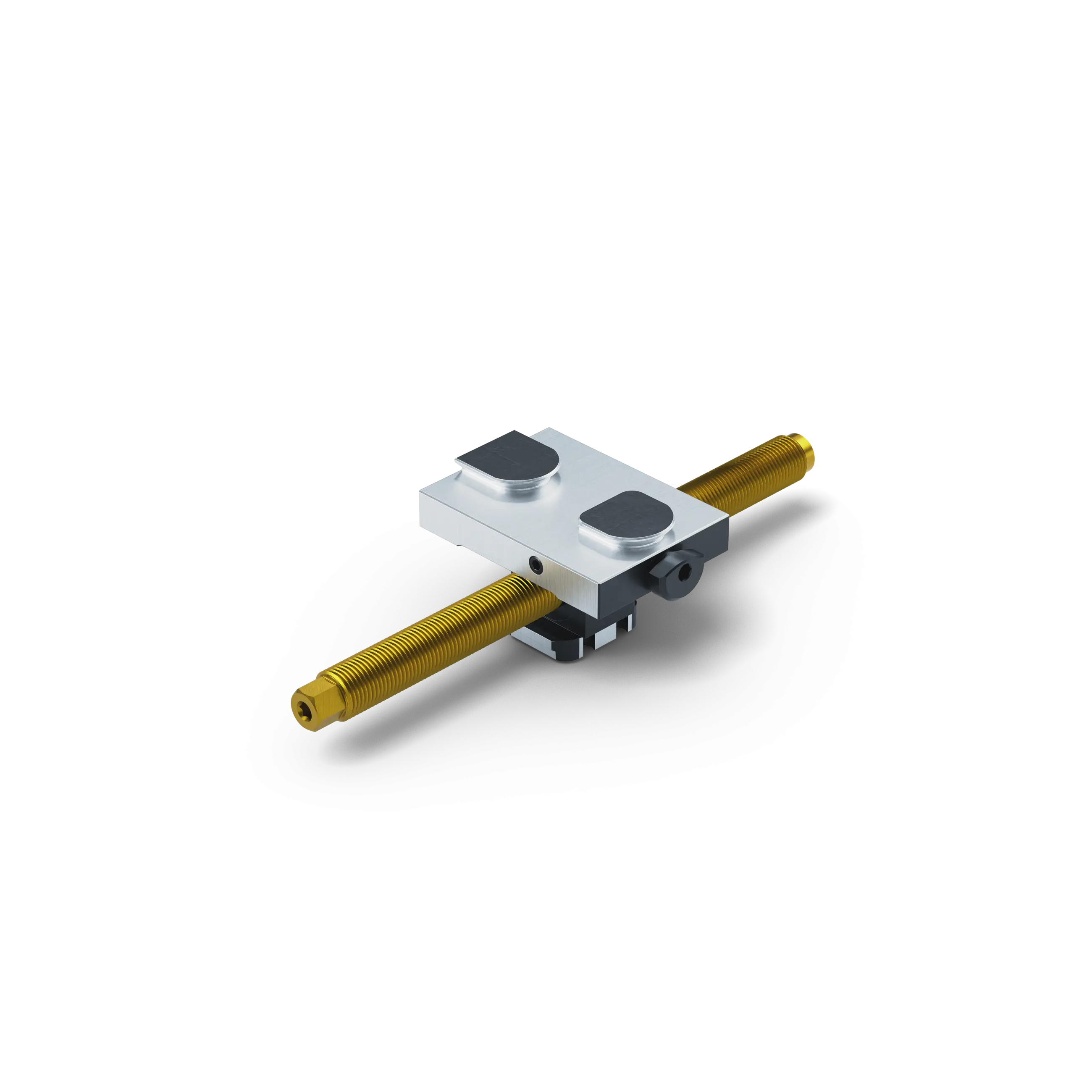

Makro•Grip® FS, Stamping Unit : Extended, with Standard Stamping Jaws

Product Code - 51410

Catalogues

1. 2025 Lang Catalogue2. Lang Workholding

3. 2017 LANG Workholding

4. 2025 Lang Speciality Products

5. Lang MakroGrip Ultra

6. Automation

7. Zero-Point Clamping

8. LANG Aero & RoboTrex Compact.

Key data at a glance

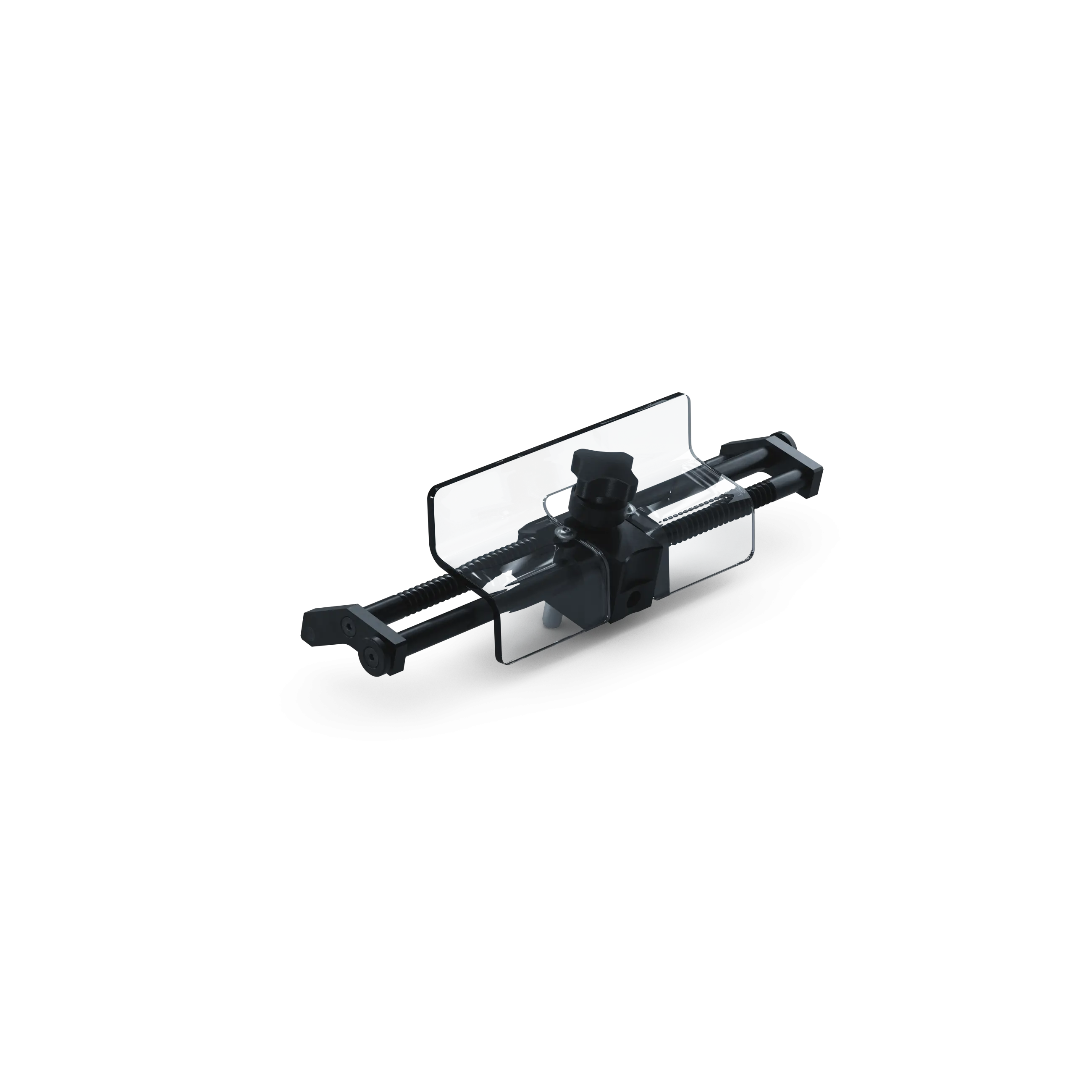

The stamping unit has undergone a comprehensive overhaul and optimization that clearly sets it apart from its well-known predecessor version. A large number of changes and improvements now make the stamping process even more convenient. The one-handed adjustment of the stamping width and the front-mounted pressure control valve ensure an even more comfortable handling than before. At the heart of this new development are its revised stamping jaws with quadruple serration in a modified design - specially designed for materials up to 35 HRC material hardness. In this extended version, workpiece blanks up to 410 mm in length can be pre-stamped. As a result, the extended stamping unit now also covers the maximum clamping range of the Makro•Grip® Ultra clamping system.

Further Information

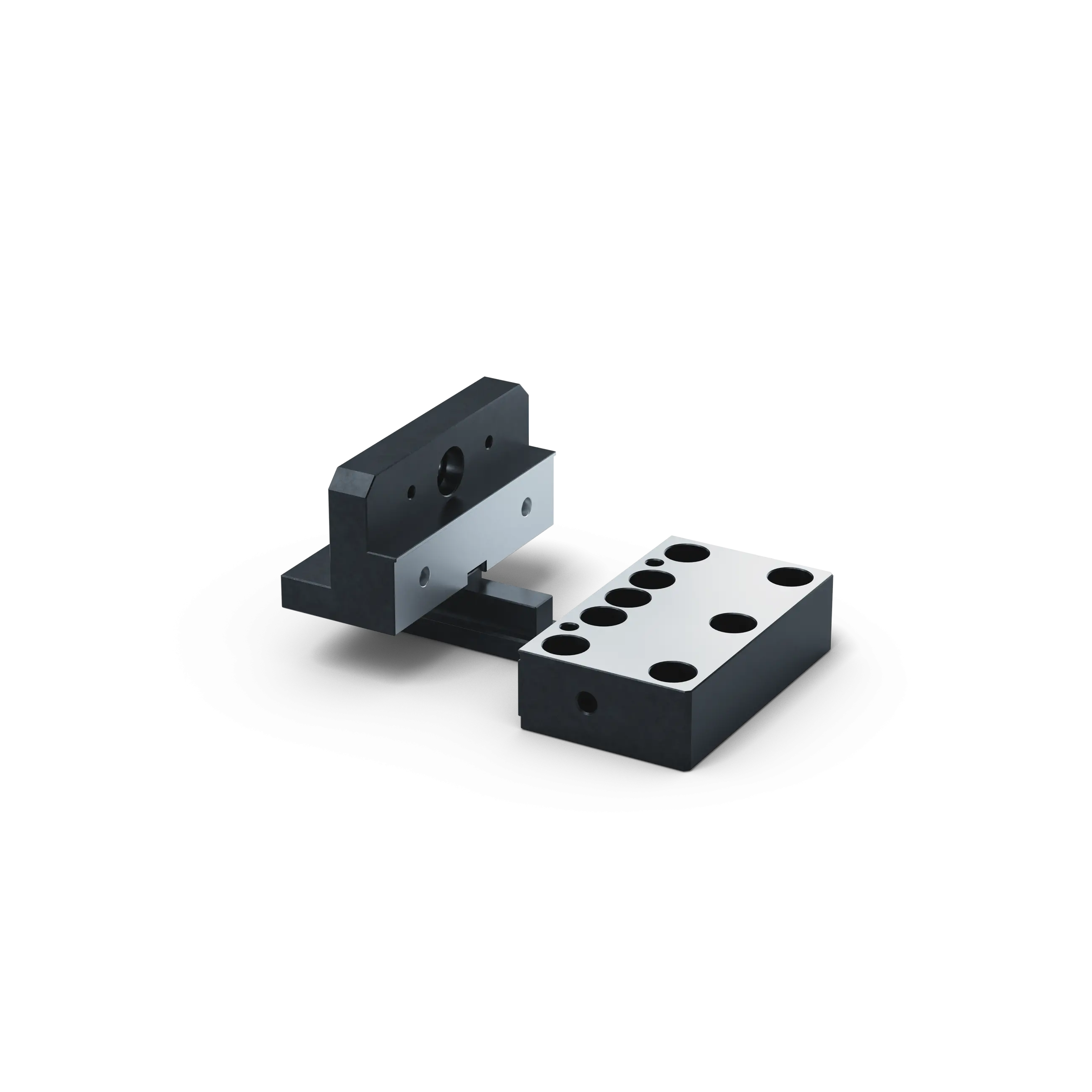

Scope of delivery: 1 x Stamping Vise

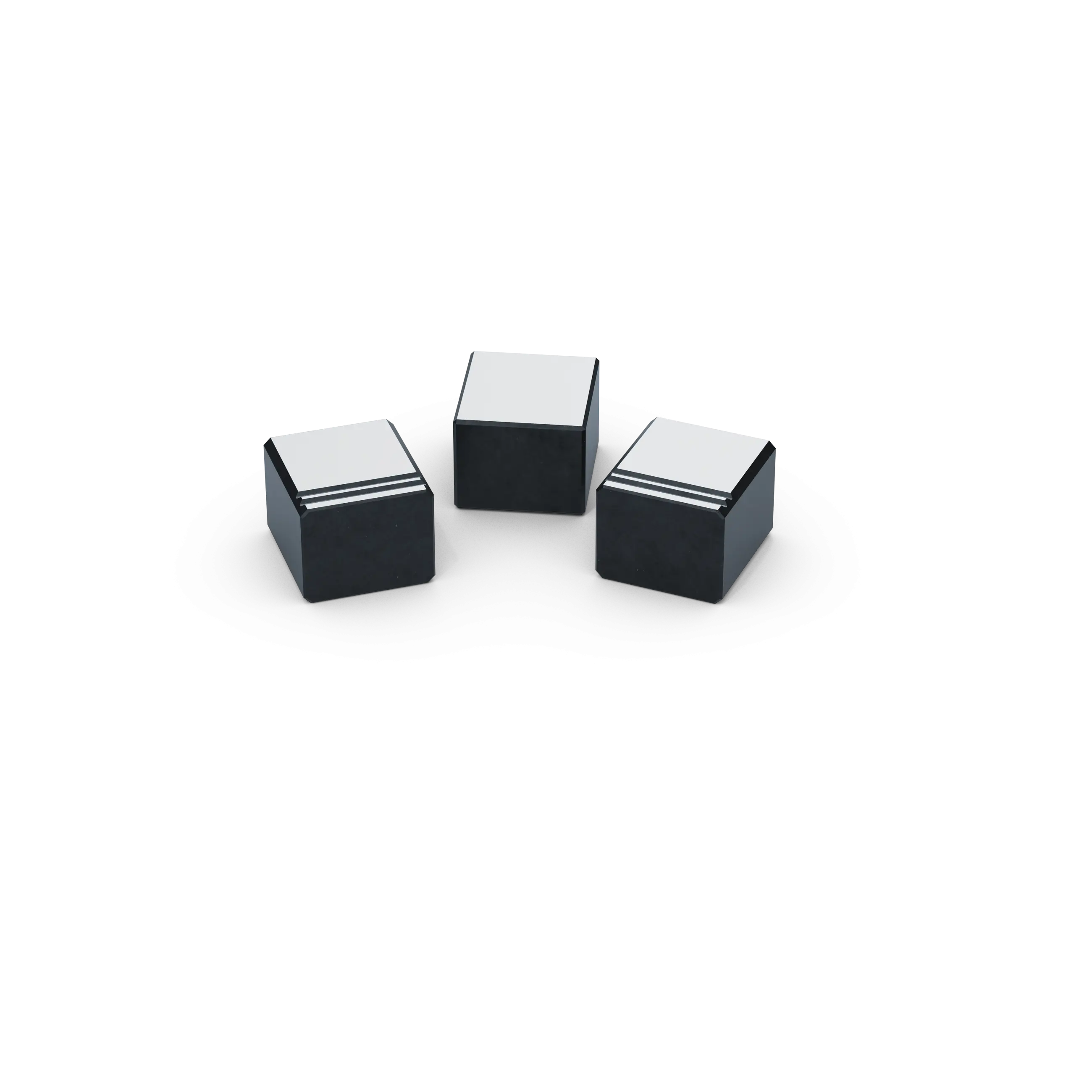

1 x 50111: Stamping Jaws, High-End, for materials up to 45 HRC

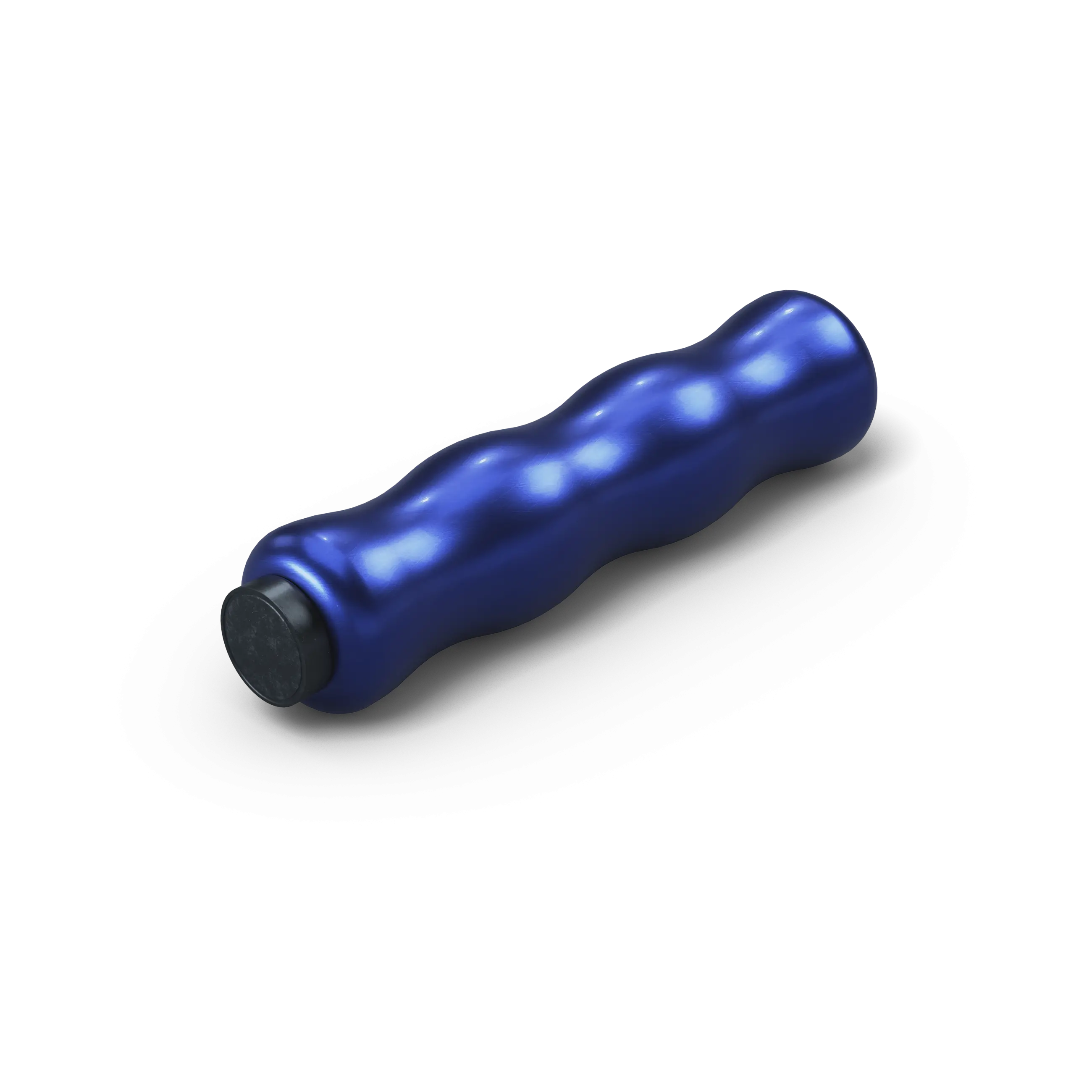

1 x 41250: Pneumatic-Hydraulic Pressure Multiplier, for all stamping units

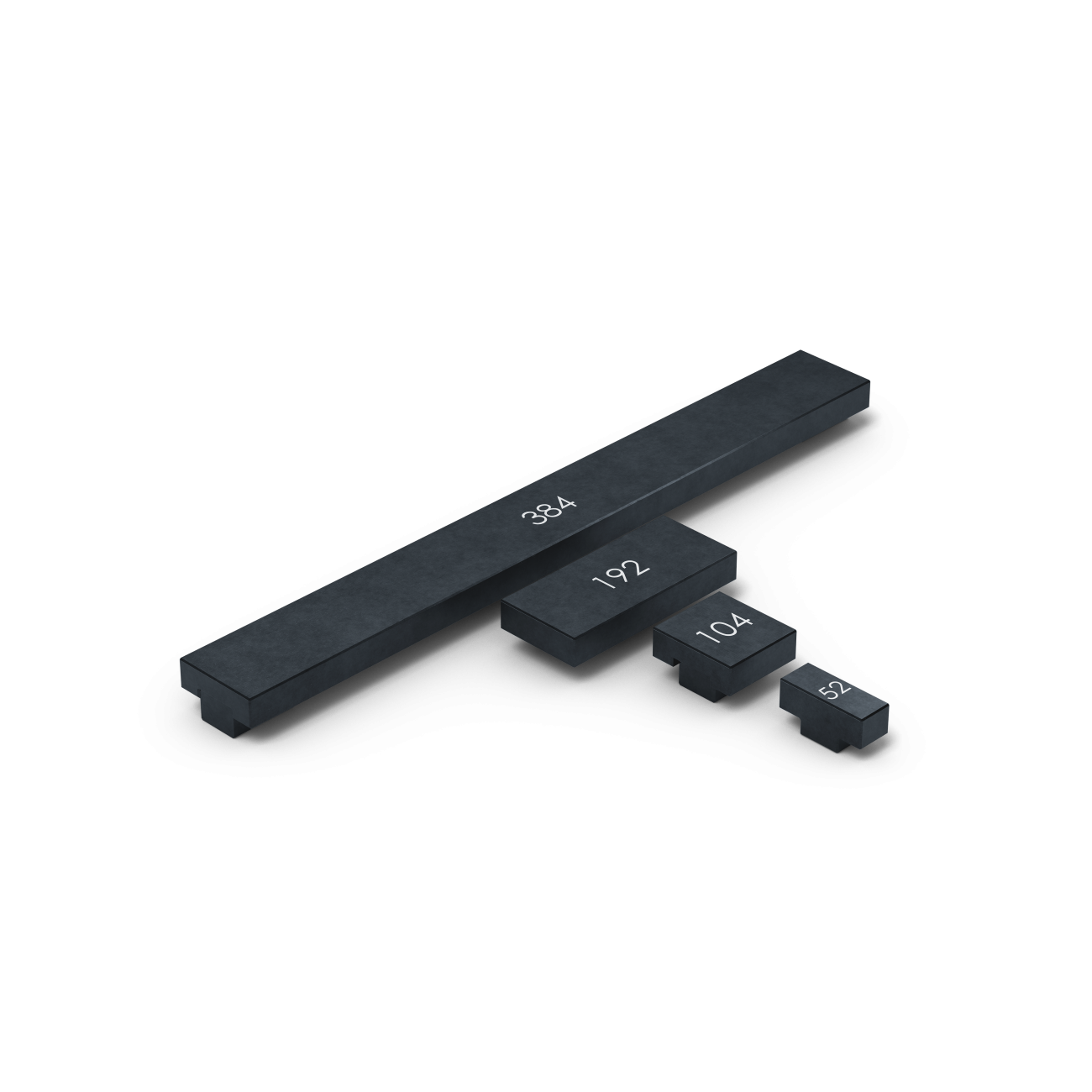

1 x 50153: Gauging Blocks, for measuring wear of Stamping Jaws

1 x 41261: End-Stop, for stamping unit

1 x Protection Shield

.webp)

Makro•Grip® FS Stamping Technology and Raw Part Clamping

The Makro•Grip® 5-Axis Vise and its unique benefits of the stamping technology has been considered „The Original“ and a benchmark in the 5-face machining of raw parts for years. Makro•Grip® FS is the further development of this product. Its compact design and high holding forces make the Makro•Grip® FS 5-Axis Vise the ideal clamping device for machining raw parts.

en

en

English

English

French

French

Spanish

Spanish

Portuguese

Portuguese

.webp)