MHM-IT

Product Code - MHM-IT

Catalogues

1. S.P.D Permanent Lifting Magnets2. S.P.D Electro-Permanent Milling System.

3. S.P.D Grinding Chucks

4. S.P.D Electro-permanent Telescopic Beam - TRETEL

5. S.P.D Electropermanent Chucks With Radial Poles

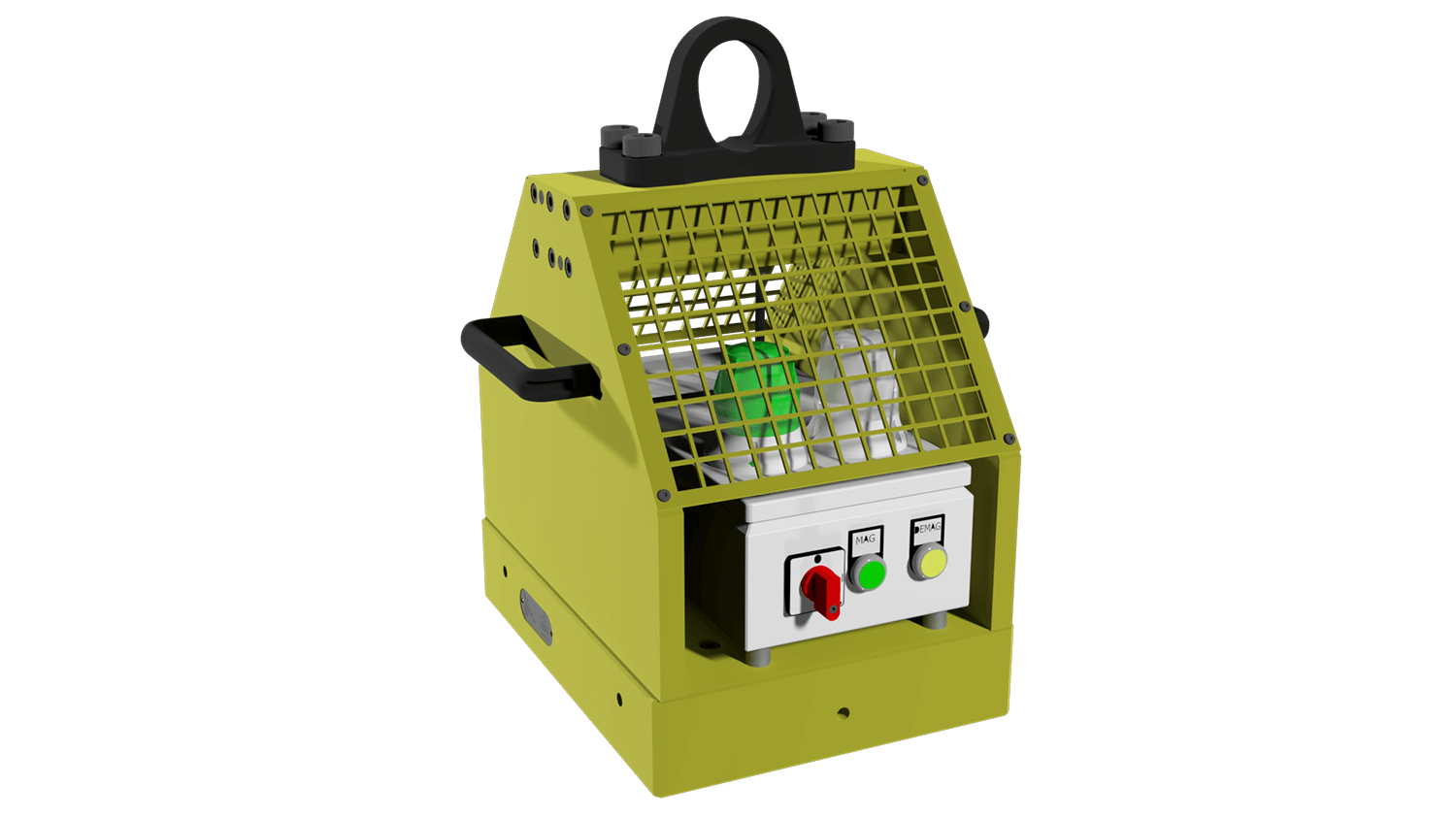

6. S.P.D Battery Powered Lifting

7. S.P.D Electro-Permanent Magnet for Grinding

8. BRISC Permanent Lifting Magnets

Key data at a glance

PRODUCT DESCRIPTION

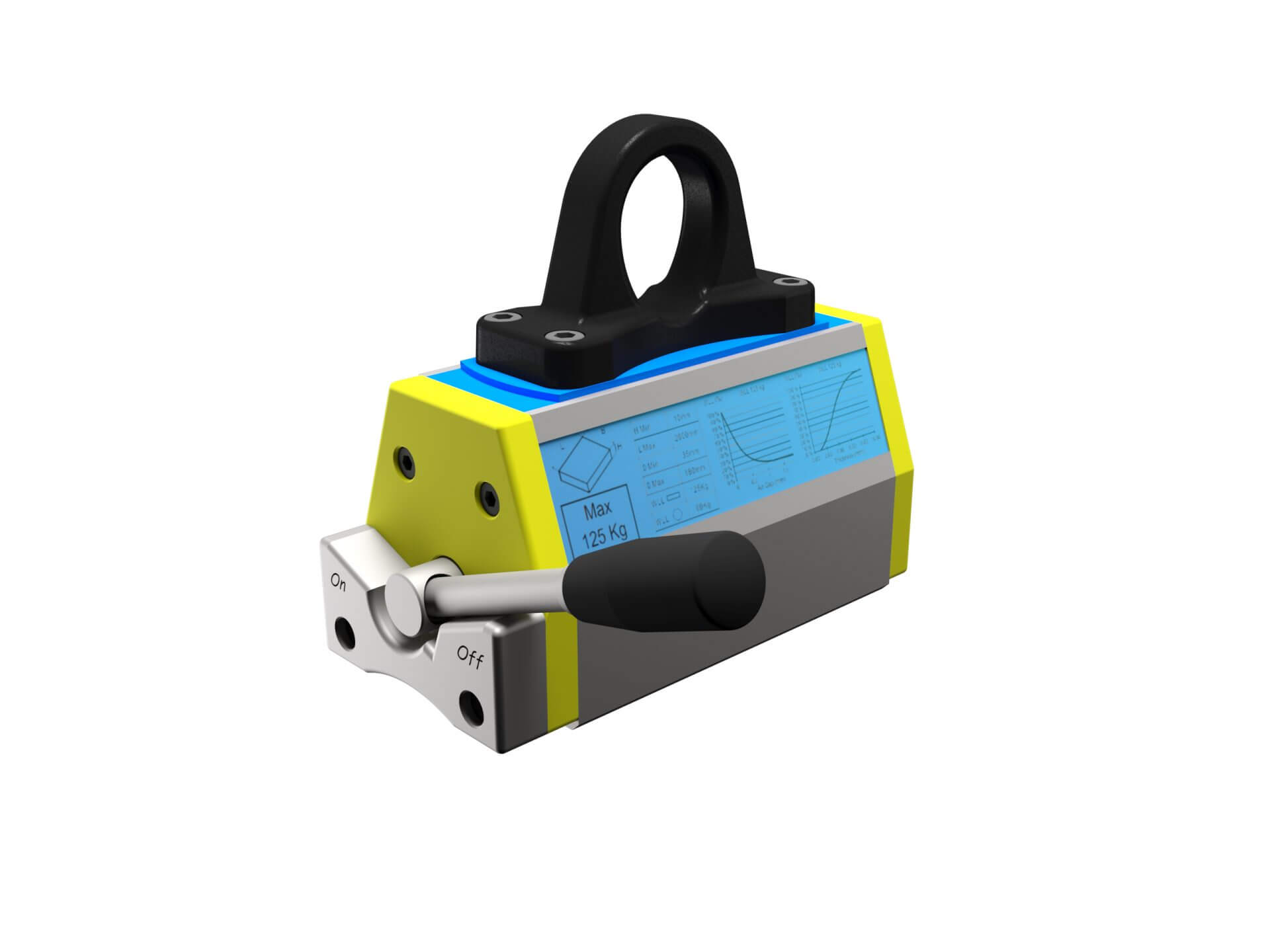

MAGNETIC NEODYMIUM LEVER LIFTERS SUITABLE FOR HANDLING BOTH FLAT AND ROUND FERROUS LOADS

ADVANTAGES OVER CONVENTIONAL SYSTEMS:

• Reduced leadtime during both loading and unloading of the work-piece;

• Increased safety: no more risky slinging operations required;

• Easily accessible and better exploitable work-piece surface;

• Increased gripping versatility in case of pieces with different shapes and sizes or with uneven surfaces or in case of small loose pieces;

• No deformation and/or damage to the work-piece caused by mechanical clamping.

TECHNICAL FEATURES:

SAFETY

The safety coefficient 3:1, required by current legal standards, has been deliberately increased by 10-15% to ensure a high level of reliability over a long period of time.

STURDINESS

The dimensions of each component have been correctly calibrated to ensure a high resistance to wear over time. Especially the Mag and Demag lever has been designed to withstand accidental impacts during free positioning of the lifting magnet. The sturdiness and interchangeability of all removable components (from the lifting hook to the containment plates and the cam guide of the lever) guarantee minimum maintenance costs.

COMPACTNESS

A lightweight, space-saving hook, integrated directly inside the cam guiding the lever stroke, can be used in confined spaces and on cranes with limited capacity.

RELIABILTY

The production process includes the homogeneous polarisation of the magnets only after the lifting magnet has been fully assembled, in order to create a perfectly balanced field on the inside. The production cycle is completed by the final testing, performed on each lifting magnet and guaranteed by the attached certificate.

Click here to download the facsimile of the acceptance testing.

HANDY AND VERSATILE

Thanks to the front hook which can be swivelled by 360° at its base, and to the bell which can be tilted by 180°, clamping operations even under the most uncomfortable and inaccessible conditions are made possible. The combination of the upper and front-mounted hook provides a single solution for any horizontal and vertical lifting needs.

Further Information

Models:

Application pictures

en

en

English

English

French

French

Spanish

Spanish

Portuguese

Portuguese